Choosing the right type of product to place on your wood can make the difference between a product that looks good but ages and falls apart quickly or a product that is built to last- and looks the part, too. When choosing between a wood stain and a wood varnish, what is the difference?

Wood stains color the wood as they penetrate the surface and are absorbed. You can choose a variety of colors for wood stains, but they do not provide much protection. Wood varnish comes in a matte, glossy, or satin finish but is typically a colorless protective layer that rests on top of the wood.

Primarily, knowing which type of product you should use- whether wood stain or wood varnish- will be the difference in if you are trying to color the wood (stain it) or if you are adding a layer of protection on the exterior surface of the wood (varnish it). While you can do both, you will need to know how and when to apply each product. Let’s take a closer look.

The huge variety of finishes for furniture is one of the subjects we will be diving deeply into during our live online workshops at Cucamonga Woodworking and you can check out our past workshop YouTube videos Here(Link to Cucamonga Woodworking)

What are the Differences between Wood Stain and Wood Varnish?

As mentioned above, choosing the right product- whether it is wood stain or wood varnish- comes down to what you need these products for in your woodworking project. Now, you can apply wood varnish over wood stain, but this is not required, and it is not necessarily a standard practice when using either of these products. For example, for many projects, you will just use one type.

Ultimately, wood stain differs from wood varnish in that wood stain always has coloration (where wood varnish typically does not- but can), is absorbed into the wood (where wood varnish rests on top), and wood stain adds no additional layer of protection (where wood varnish enhances the wood’s durability).

You can see that these two products are meant for very different purposes based on what they are designed to do. Clearly, they function very differently on the wood that they are applied to. Still, many people who are new to working with wood or doing projects for themselves can get these two products confused and consequently choose the wrong type of product for their project.

To help distinguish the different uses for wood stain versus wood varnish, let’s take a closer look at a few of the areas that these products differ the most.

Wood Stain vs. Varnish Color differences

One of the main differences between wood stain and wood varnish is the color of the actual product. Of course, the color of wood stain is ultimately going to serve the end goal of the product itself. This means that a colorless wood stain would be relatively pointless, but a colorless wood varnish is relatively standard (although you can find wood varnish in a few color options).

When it comes to wood stain, the color is the main descriptor that will set this product apart and set one wood stain product apart from another wood stain product. Let’s say that you have just completed constructing a new wooden deck or patio in your backyard. Now, while you could apply a sealant and leave the natural wood look, most people will apply a stain first for the aesthetic appeal that it brings.

Wood stain can be selected in various colors depending on the brand you are working with. You could choose for your wood to appear more brick red or have a more natural dark brown tint. Regardless of which color option will work well with the rest of your aesthetic, you can choose the right color of wood stain to apply to your project.

In the case of the wooden deck, you could apply wood stain to a few sample pieces of the same type of wood that you used to construct the deck, and then you can decide which sample will work as the best color option for your project. From here, you can stain your deck to add the flair of color that you are going for. Then, you would apply some sealant (which could even be a varnish) to add the durability that the wood stain will not have.

However, when it comes to color in wood varnish, you should not expect to find coloration, as most types of wood varnish are relatively colorless (or they enhance the natural color of the wood that they are applied to). Still, you can find some types of wood varnish that have color applied to them– this is just not the main purpose of this type of product.

Instead, wood varnish will more typically be colorless and come in the options of a glossy, satin, or matte finish. This is standard like most types of paint- either there will be a lot of shine, a little bit of shine, or no shine at all on the surface after the (clear) wood varnish has been applied to your wood.

While these application options are nice to choose from, wood varnish is not ultimately applied for the color enhancement that it can provide. Instead, it is used for durability (but more on that later).

Does Wood Stain or Varnish Get Absorbed By the Wood Better

Yet another key difference between wood stain and wood varnish is the level of absorption of the two different products. Primarily, wood stain is intended to be absorbed into the wood that it is applied to while wood varnish is meant to rest on the outer surface and provide an enhanced layer of durability.

With this, whichever wood stain you choose will be absorbed into the wood fibers and alter the color of the wood to the color of the wood stain you have selected. Now, the wood stain will likely need to be applied on all visible sides of the wood project that you are working on for the color to be applied evenly, but it will still soak through.

This does not harm the wood that you are working with, but it does change the color of the wood permanently (except for any areas that the wood stain wears off). Of course, if you are working with any exotic wood, you will want to test out a sample of any product on it before applying it to the entire project- to spare yourself the pain if something goes wrong.

On the other hand, in terms of absorption into the wood with wood varnish, this is not intended. The wood varnish- if it has a high level of thinner in it (meaning it is more liquid than not)- might seep into the top layer of the wood you are working with, but this is not what it is designed to do.

Instead, the wood varnish should adhere to the outer layer applied to and then harden to form its own external layer. This is the layer that will protect from wear and tear and exposure to the elements. If the wood varnish were absorbed into the wood like wood stain, it would not serve the same protective purpose that it was designed with.

Stain vs. Varnish Durability

Just like the color application is the main purpose of using wood stain, adding an enhanced durability level is the main point of applying a wood varnish. Consequently, the wood varnish will be highly durable than wood stain considering wood varnish is made to be so (and add protection to the wood you are applying it to).

When it comes to wood stain, this adds essentially no durability to the wood that it is applied to. The wood stain will enhance the coloration of the wood that it is applied to, but most wood stains are not designed to protect the wood they are applied to.

Instead, most of the time, when you are using a wood stain, you will need to apply a finish or sealant to the project to ensure that the wood stain does not chip due to natural wear and tear or exposure to the elements. Without an additional protective sealant placed on top of the dried wood stain, you run the risk of your project chipping and leaving you with the need to re-stain your entire project after sanding down the chipped parts. Obviously, how seriously this gets depends on the exposure to the elements, wear, and tear that the project receives.

This is not the case with wood varnish. Wood varnish acts as a sealant in this way (and some sealants could be considered to fall under the category of wood varnish). Wood varnish is applied on the outer surface of the wood but does not penetrate the wood. Instead, it adheres to the wood’s exterior and forms a unique bond that protects it from peeling away.

Additionally, Wood varnish forms a layer that will protect the wood underneath it. This means that if you have applied wood varnish to your dining room table, rocking chair, or exterior deck, you should not see general wear and tear the same way you would see it without applying this product.

The level of protection that the wood varnish provides to the wood that it is applied to will depend on the ability of the particular wood varnish you have chosen to adhere to the wood you are using and the quality of wood varnish that you have chosen. If you are using low-quality wood varnish, you may find that you have to reapply it sooner than by using a high-quality wood varnish and appropriate application methods from the start.

Consequently, using a high-quality wood varnish will save you money down the road as you will have to reapply it much less frequently. It should hold up better against natural wear and tear and exposure to the elements, especially as compared to low-quality wood varnish. You can rely on high-quality wood varnish to last for a while, and it will help to protect the wood beneath its surface layer to appear (and be) beautiful, intact, and ready to showcase.

How to Choose the Right Type of Wood Varnish

If you are looking for a wood varnish, you have likely noticed many different types. And, unless you know the differences in the various types of wood varnish, you may not be able to make the right choice for your project. Various types of wood varnish exist for different purposes, and choosing the right type of wood varnish is incredibly important for the varnish to do what you expect it to do.

To choose the right type of wood varnish, consider the following steps:

- Know the purpose of the wood varnish for your project.

Regardless of what you are applying a wood varnish too, you are likely using this type of product to support your woodworking masterpiece, to make it more durable, waterproof, UV resistant, and so forth. You want your woodworking project to be built to last and protected from the elements, and the right type of wood varnish can certainly do the trick.

However, there are many different unique purposes that you may find for your project. For example, you might need a wood varnish to protect your smaller wooden projects exposed to lots of handling and consequently exposure to oils from the human hand. On the other hand, you might need a wood varnish that can protect your exterior wooden deck from heavy rain, sleet, and sunshine.

Or, maybe you are looking for a wood varnish for your boat- yes, a marine wood varnish exists for your submerged vehicle of choice. But, as you can see, the various needs of these different types of projects will lend you to be able to choose a unique type of wood varnish that can most directly and effectively take on the specific need that your woodworking project requires.

- Find the wood varnish that meets the needs of your project.

Once you have determined the wood varnish’s purpose that you will need for your woodworking project, you can find the right wood varnish to meet this need. From here, you will want to be well versed in the various types of wood varnishes available and what they do.

Let’s consider the following types of wood varnish so you can see how these would meet the needs of your project.

Polyurethane Varnish

If you are looking for a varnish that will need to hold up to lots of natural wear and tear (such as placing varnish on your hardwood floors), polyurethane can be a great choice. This type of varnish requires the use of a primer beforehand, but it does not change colors (or turn yellow) much from its original use.

Keep in mind that polyurethane is not highly UV resistant, meaning it should not be used on projects that will have much exposure to the sun (unless you can find a UV resistant brand or another topcoat to place on the project). Still, if you are looking for a highly durable wood varnish that will not soak into your wood too much, this is a great choice.

I’m a fan of Minwax products (Like this wipe-on poly, check the price on Amazon here)

Acrylic Varnish

If you are looking for a water-based wood varnish and can be used over wood and other surfaces that might be found on your projects, then acrylic varnish may be a good option. While this is a durable material, it is not intended for projects that will receive a high wear and tear level (like hardwood flooring). Instead, this can be a great option for smaller woodworking projects or projects like dining tables that will have table cloths over them to protect from heat, liquid spills, and so forth.

Acrylic varnish is considered to be non-toxic (although be sure to check the specifications of the brand you intend to use), so it is commonly used on wooden projects like cutting boards or wooden utensils that will need to remain durable but not be toxic when food is placed on them. Sargent has a good line of acrylic varnishes (Check out the item on Amazon Here)

Of course, varnishes like polyurethane should not be toxic once dry. Still, you will have to be more careful about cutting or chopping any tiny shard of this type of varnish off (whereas a non-toxic acrylic varnish would cause fewer concerns).

Exterior Varnish

If you are looking to apply a wood varnish to your project that will remain outdoors for the majority of its time, then you need to find a wood varnish that is specifically designated for exterior use. Exterior wood varnish is known to become slightly yellow, but it is also designed with a high level of protection against exposure to the elements such as rain, the sun, and so forth.

When choosing to apply exterior varnish, be sure that you are applying it carefully. This type of wood varnish tends to be slower to harden (or cure), so you will need to apply it diligently and in more but thinner layers. Then, be aware that exterior varnish may discolor a bit. Still, it should prevent your wood from any damage (and also tends to prevent fungal or bacterial growth as well as elemental damage).

Marine Varnish

Marine varnish is specifically designated for use on boats and marine purposes- when a wooden object (like a large boat or vessel) will be submerged and needs protection from any leakage or cracks happening to the wood. Unless you are looking to apply wood varnish to your boat/vessel, this option will not apply to you.

However, if this is your intention, then it is helpful to know that marine varnish has been specifically crafted with the wear and tear underneath a boat would come into contact with. Consequently, you will find that marine varnish is highly protective against exposure to water, and it is also flexible enough to bend with the wood as the wood reacts to the pressure of the water underneath it.

- Carefully apply your wood varnish based on the specifications of which type you chose.

Now that you know which types of wood varnish you should use for which types of woodworking projects, it is important to note that you will need to carefully apply the wood varnish based on the specifications of the brand and type of wood varnish that will meet the needs of your project.

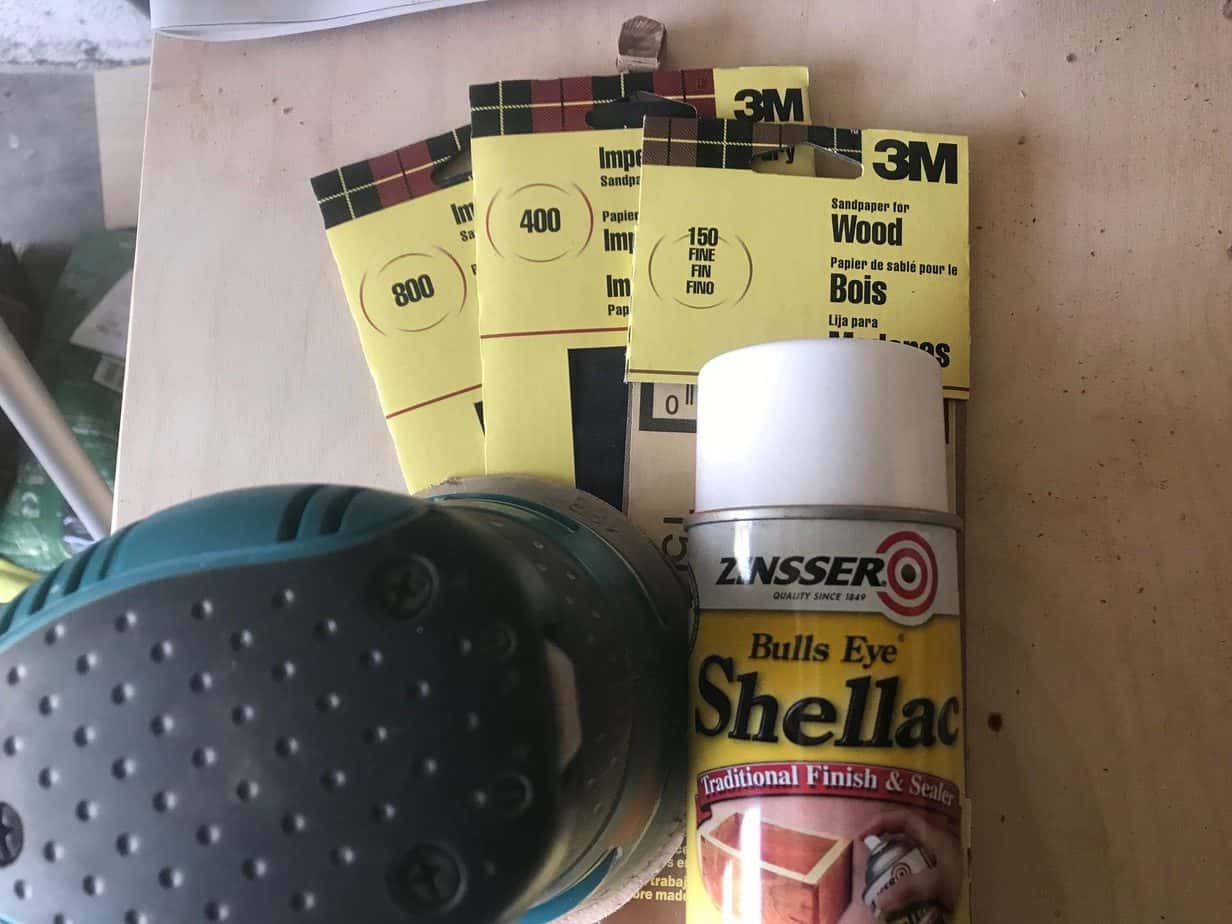

Specifically, you will want to pay attention to the level of grit that you will need to use when sanding down the surface before application, any need for the use of a primer (or at least a thin layer- the most common option), and, of course, the cure time that is expected for your project. Knowing all of these will be essential to the correct and effective application of whichever type of wood varnish you are using on your woodworking project.

How to Choose the Right Wood Stain

Now, switching gears from wood varnish to wood stain, knowing how to choose the right wood stain will look a lot different. Here, you will not be concerned about the type of wood stain (as there are not the same types of options as there are when it comes to wood varnish). Instead, you will be focusing on choosing the right color for an interior or exterior project and assuring that you apply it correctly.

To choose the right wood stain, consider the following steps:

- Pay attention to the purpose of your project.

Knowing whether you plan to leave the project indoors or outdoors, what the point of the wood project you are working on will be, and any other details can help you find the right type of wood stain. For example, you can find a more natural color or one that will help your project stand out. Knowing the point of the project will help gear this in the right direction.

- Estimate the amount of wear and tear that your project will receive.

Along with knowing the project’s point, you can estimate the amount of wear and tear that your project will receive. If you imagine that your project (like a wooden deck or hardwood flooring) will receive a high level of wear and tear- or exposure to the sun, rain, etc.- then you can choose a wood stain (and sealant) accordingly.

- Choose the right color of wood stain.

Choosing the right color of wood stain can be hard, considering it is a highly personal choice and is largely based on the aesthetic you hope to achieve. Still, you can choose a color of wood stain that will enhance the natural wood grain of an impressive type of wood, or you can choose a more bold color of wood stain if you want the color of the wood stain to leave a lasting impression.

- Apply a sample on a small section of extra (or a non-visible section of) wood.

After choosing the right color of wood stain (or what you think is the right color), you will want to test out a sample on the same type of wood that you are using to be sure. This can help you to avoid any mishaps or regrets in choosing the wrong color. Ideally, you can do this with a small section of extra wood exposed to the same type of lighting/elements that your final project will be. This can really help with deciding on the right color.

If you do not have any additional wood or sample pieces left, then you can apply the wood stain to a less or non-visible section of your project before applying it to the entire project.

Either way, here, you can see what your lasting project will look like without applying to the entire project from the start. Then, if you want to change your mind, you have a lot more wiggle room (and a lot less effort) to do so.

- Correctly apply the wood stain.

Knowing how to apply the wood stain correctly will obviously greatly impact your project’s final results. Be sure to check for the level of sanding required before use, any special primer or other treatment that the wood needs to receive before applying the wood stain, and how thin or thick the layers of wood stain should be when applying them.

You will generally want to apply thinner layers of wood stain, and as they dry, you can always go back and apply more layers for complete coverage. Just be sure that the layers are dry between applications, as not doing this could result in quick peeling.

- Apply a sealant (optional).

Finally, when choosing the right wood stain for your project, it might not require the use of a sealant after application.

However, for any project that will receive a decent amount of wear and tear (and especially any project that will be mainly outdoors and consequently exposed to the natural elements), you will want to choose a sealant that meets these needs and can add the layer of protection to the stain and the wood that the stain cannot provide by itself.

Interestingly, you can choose a type of wood varnish to go over the wood stain after the wood stain has completely dried. In choosing the right type of wood varnish for this purpose, you can benefit from the color (from the wood stain) and protection (from the wood varnish) to take your project to the next level.

Many people also use shellac, which is not technically considered a wood varnish but acts as a sealant. With either option you choose, the sealant will help keep the color of the stain on the wood and water, UV rays, and mold off the wood.