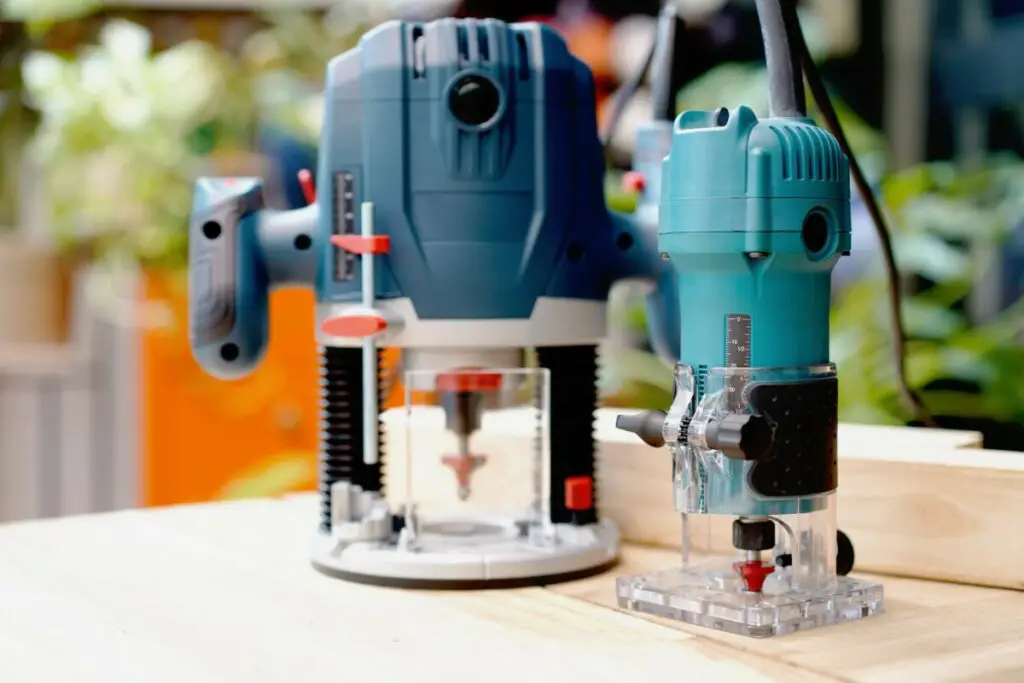

Fixed base and plunge routers are both excellent tools in woodwork and are often referred to as the most versatile power tools in the world. They provide a plethora of potential uses and projects in carpentry. They serve the same purpose, but each has certain specialties in terms of application and projects best suited for the tool.

Plunge routers can be used for all projects and do everything a fixed-base can. A fixed-base router is a less versatile tool but can be the best option for specific projects. There are options available to purchase a combo routing kit with a single motor that can be changed to both router types.

While plunge routers are generally a more versatile option, there are some projects in which a fixed-base would serve as a better tool. It is important to understand the differences and know what your intentions are before purchase to ensure that you make the best decision for your woodworking needs and projects.

Fixed Base Router

As the name suggests, a fixed base router has a fixed base, but it also has a fixed cutting bit. This is excellent for the ease of use and precision of the cut but can limit options in working because the cutting bit cannot “plunge” to a new depth once you have started cutting. They are, however, more precise in the depth of the cut, once set, than a plunge router because they do not move.

This extreme precision makes fixed-base routers an excellent option for edgework and joinery projects. The fixed base, light weight of the tool, lower center of gravity, and precision in cut depth all work together to limit space for human error. This type of router is also ideal for table mounting, whereas the plunger router can be used in a larger variety of situations.

Another advantage to the fixed router is that they are generally more cost-efficient than plunge routers. This can be attributed to the fact that fixed base routers have fewer compound parts.

The largest disadvantage to the use of a fixed base router is the lack of ability to adjust and plunge to a new depth in the wood. This is solved through the use of a plunge router.

Plunge Router

A plunge router can do everything that a fixed base router can do, and more. These routers have spring-based arms on either side, allowing the user to plunge the cutting bit to different depths while in use. Fixed-based routers, however, require you to stop the machine and reset the depth before continuing. For this reason, plunge routers are generally considered to be more versatile and convenient tools than their fixed base counterparts.

Plunger routers require more skill and decisions from the user. The tool is heavy at the top and requires a steady hand to keep the cut at the desired depth. The plunger router can also be set to cut at a specific depth, and then adjusted as the worker chooses during the cut. Because of the increased potential in use, the plunge router also requires a longer learning period for new users than the fixed router, which is a straightforward approach.

These routers are a wonderful decision when used for making cuts from the top or center of the board. This is an option unavailable to fixed-base routers. Because of this difference, they are excellent for uses such as fluting, insets, grooves, rebates, dados, and mortices. Like fixed base routers, plunger models can also be used for edge work, especially when utilizing a round-over cutting bit to profile edges.

While the plunge router can be used for a larger variety of projects, it also has its disadvantages. The largest drawback to a plunge router is that while it can perform edgework, it cannot do so with the same level of quality and precision provided by a fixed base router.

Which Type Do You Need?

With this foundational knowledge, we can now assess the real question at hand: which type will best serve my needs and situation?

A fixed base router is a better option for those seeking a tool for similar woodwork and cuts such as profiling edges or cutting dovetail joints. This is also the ideal tool for those who need or choose to work exclusively with a routing table. This model will provide you with ease of use, extreme precision, and excellent accuracy.

For novice woodworkers that lack a specific need or use for the router, but are purchasing one to increase their options in the future, a plunge router is most likely the best choice. They are more versatile, providing a larger range of possibilities for you in future projects.

While they are often more expensive than fixed-base routers, they can also be set at a specific depth and used as a fixed base router for projects that benefit from increased precision. This applies to the larger group of woodworkers, pertaining to all but a few specific situations.

Can You Use Both Types of Router?

There is, however, a more innovative option for those who are either still unsure of which tool they’d prefer, or those who feel they would rather have both as options in their future work.

Many of the larger tool companies are now offering a combo routing kit. This is an excellent option for those who feel they would benefit from the use of each router in their projects. This combo kit provides a single motor that can be attached to a fixed or plunger base depending on the nature of the woodworking project you are working on at the moment.

While this does help in eliminating the need to choose one or the other, it is important to keep in mind that this option is less cost-efficient. Most consumer options are cheaper than the purchase of both routers separately, but will still cost more than the purchase of a single router.

Even with the increase in cost, this is still a highly recommended option. It will allow the user to adjust their tool to each situation’s requirements

What Should You Look for in a Good Router?

While all types of routers are considered to be versatile tools in woodwork, this is only true of quality models that will help fulfill your specific needs. There are several factors that should be accounted for in the selection and purchase of a router. Below are a few of the largest details and aspects to investigate in each model. Most importantly, keep in mind the uses you have in store for this router and how each model will measure up to those needs in comparison to others.

Horsepower Rating

The measure of how much power your router can generate is one of the most crucial factors in determining which model suits your needs best. Generally, a router will need at least 2 HP to be an effective cutting tool.

Keep in mind that the higher the HP, the heavier the tool will be, which can become cumbersome in smaller detail work. For those who intend to mostly work mounted to a table, higher power will be key. Routers are generally worked much harder when mounted to a table.

Controlling Motor Speed

Depending on the project and especially on the material being cut, the speed of the router will make a large difference. For all but lighter weight models, variable speed control will be an invaluable tool. This will provide you the freedom to vary the speed for wood vs plastic or other materials, and even begin with a soft start.

Collets

A proper collet makes an incredible difference. Poorer quality collets are made from cheap steel which wears quickly and makes hard work of the cut.

Quality collets, however, are made of tapered steel, fitting into a tapered shaft. They are more efficient and last longer than weak collets. It is important to evaluate the quality of the collets before making a purchase, and it is especially helpful to have a variety of sizes.

Plunge Depth

In the plunge depth, the router needs to have the ability to lower the collet to the bench top. If the plunge depth is shallower than this, it will make a large portion of your projects much more difficult than necessary. Any router than can plunge deeper than this would be an incredible benefit to you and increase the potential of your work.

“Router depth” information provided by manufacturers refers to the amount of space a router can move up and down the plunge legs. It is rare for a collet to be plunged through the router base, but can be an invaluable asset in improving the cut depth.

Plunge Lock

For this part of a router, there are two options: a separate clamping lever, or twist knobs. For medium or larger-sized routers, it is extremely important to have a separate clamping lever. On smaller models, however, it is possible to have the twist knobs and not experience too much inconvenience. Most woodworkers prefer the separate clamping lever option.