The best wood for woodworking has a moisture content of between 15% to 25%. Such wood is strong and produces excellent products in any project. If you have overly dry wood with a moisture content of 8%, should you still use it?

Wood can’t be too dry for woodworking because it gets very brittle and will be susceptible to a lot of damage, including cracking, splitting, and shearing when you attempt to plane, saw, or nail it. The wood moisture level should be the same as the final environment where the finished work will be because the wood will reach equilibrium with its location.

The rest of the article will explore other topics related to the question in detail, including the moisture properties of wood and how moisture affects various wood properties.

Wood Humidity and dryness is one of the topics we plan on discussing during our live online workshops at Cucamonga Woodworking. You can watch our past workshops on YouTube here(Link to Cucamonga Woodworking)

Moisture Properties of Wood

Wood is a hygroscopic material, meaning it’ll absorb and lose water to the atmosphere. It gains water through capillary action, diffusion, and as vapor through the cell walls.

Wood’s moisture content refers to the amount of water a piece of wood contains relative to the wood itself and is expressed as a percentage.

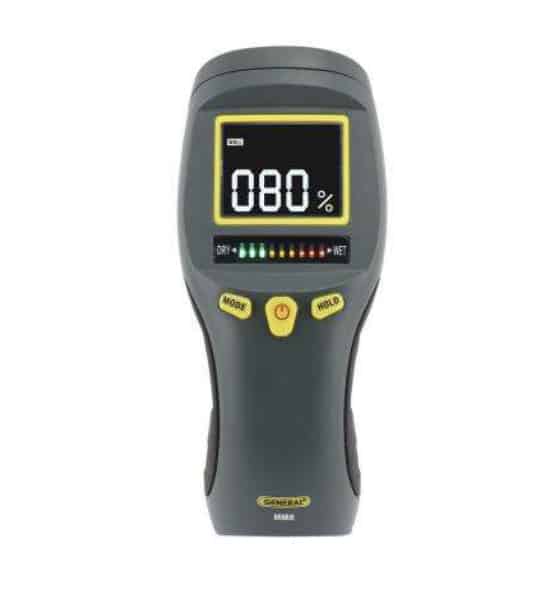

You can check the moisture level with a moisture meter. If you want an accurate and useful measurement then the cheaper meters are useless. The mini Ligno moisture meter is about the cheapest I would buy if I really needed to check the moisture(which I don’t). Check out the specs and get something with similar accuracy if you do need one. Here is a link to the meter on Amazon: Lignomat Moisture Meter Mini-Ligno E/D

Since wood is derived from a tree’s vascular system, it comprises fibers made of tubular cells that absorb and store water. When wood fibers absorb moisture, the water is first held in the cell walls. When the cell walls get saturated, the additional water is stored in the tubular cells’ cavities.

The moisture stored in the cell walls (known as bound water) affects wood behavior, while the water contained in the cells (known as free water) merely adds to the wood’s weight. It also increases its susceptibility to rotting and fungus, and mold attacks.

The amount of bound water in wood ranges from 20% to 40% and is expressed as a percentage of the wood’s oven-dry weight.

The point where cell walls in the wood are thoroughly saturated with water is known as fiber saturation point and is an important benchmark for wood shrinkage and decay. At this point, wood fibers are fully saturated, but the cell cavities are empty.

From there on, the wood stores moisture inside cell cavities until it reaches its maximum moisture content. The amount of free water that wood stores depends on wood density and varies from species to species. For instance, pine can hold as much as 143% moisture, beech 120%, while balsa holds up to 260%.

In living trees, the moisture content ranges from 30% to 300% depending on the season, the part of the wood, and tree species. After processing, greenwood gradually loses moisture content to the atmosphere, starting with the water held in the cell cavities.

In newly sawn wood, the moisture content ranges from 40% to 200% but gradually drops between 8% and 25% in seasoned wood. Local climatic conditions, particularly relative humidity and air temperature, determine the wood’s final moisture content.

Even then, air-dried wood’s water content is subject to limited variations in response to prevailing weather conditions.

You can calculate the amount of moisture in a piece of wood based on its current and oven-dry weight. You can also use a portable electric moisture meter. The meters use changes in wood’s electrical properties as a function of varying moisture content.

Try keeping the moisture level in your workshop constant, especially when working with kiln-dryed wood in a humid envirnoment. My article on workshop humidity has good additional information. (Link Here)

The Importance of Moisture Content in Wood

Moisture content is of primary importance in woodworking because water affects all wood properties. For instance, when the very light balsa wood absorbs a lot of water moisture because it has huge cell cavities in its structure.

Since wood is continually absorbing and losing water, the moisture content is an ongoing concern in woodworking.

Here are some of the critical wood properties affected by its moisture content:

Mechanical Strength

Wood’s strength refers to its ability to resist forces that could potentially change its size and shape. Wood density and moisture content alongside force magnitude and direction affect its ability to withstand such forces.

Since wood is anisotropic, its strength properties vary drastically across the grain and along the grain.

Some of the wood’s mechanical properties affected by moisture content include:

- Strength in tension and compression

- Elasticity

- Bending strength

- Hardness

- Cleavage

- Impact absorption

Density is the best strength indicator of wood strength as highly dense wood species have the greatest strength. Moisture content impacts wood strength when it falls below the fiber saturation point.

Most wood strength properties will increase following a decrease in moisture content, while wood defects such as knots, deformities, and grain deviations are strength-reducing.

Shrinkage and Swelling

Wood is an anisotropic material, i.e., the properties it exhibits are tied to the wood grain’s direction. As a hygroscopic and anisotropic material, wood experiences drastic changes when moisture falls below the fiber saturation point.

During the drying process, greenwood doesn’t lose water and shrink uniformly, resulting in various dimensional shrinkages. The dimensional changes happen along three planes—radial, axial, and tangential planes.

- Radial shrinkage. It varies from 2% to 8%, with most wood species falling in the 3% to 5% range.

- Tangential shrinkage. It varies from 3% to 12%, but most woods fall in the 6% to 10% range.

- Longitudinal shrinkage. It ranges between 0.1% to 0.2% and is often inconsequential.

Here, the percentage values refer to the changes that occur when the wood moves from green to oven-dry condition.

The differences in swelling and shrinkage in the three planes are attributed to the cell wall structure. Microfibrils’ orientation in secondary cell walls accounts for the difference between the lateral (tangential and radial) and axial shrinkage.

Wood density, mechanical stresses, moisture content, chemical extractives, and wood abnormalities affect wood swelling and shrinkage.

Dimensional changes in wood can wreak havoc in woodworking pieces:

- Tightening or opening of joints

- Warping

- Case-hardening

- Honeycombing

- Cracking

- Alter cross-sectional shape

Acoustic Properties

Wood is a popular material for musical instruments and acoustic materials because it produces sound when struck directly and can amplify or absorb sound.

The pitch of the sound produced by a wooden surface or instrument depends on the frequency of vibration in the wood. In turn, the frequency of vibration is influenced by wood’s density, dimensions, elasticity, and moisture content.

High-density wood in smaller dimensions produces high pitch sounds, explaining the sizes of most wooden musical instruments.

When sound waves strike a wooden surface, they’re partially reflected and partially absorbed, causing the wood to vibrate. In musical instruments such as guitars, violins, and organ pipes, the sound is amplified but absorbed in wooden partitions.

Although wood absorbs a tiny amount of acoustic energy, its unique structure, porous fibers, and empty cells magnify the absorption rate up to 90%.

Sound travels at a speed of 3,500–5,000 meters (about 11,500 –16,400 feet) per second across the grain. That means sound travels through the wood at a rate that’s ten times higher than that of air.

When traveling along the wood’s grain, sound travels at 1,000–1,500 meters (3,300–4,900 feet) per second. High moisture content in wood reduces the speed at which sound travels, contributing to faster dumping of sound.

Conclusion

Wood is a hygroscopic and anisotropic material, and because of this, it has an interesting relationship with water and moisture. Greenwood loses much of its water during the curing process until it falls below the point of fiber saturation.

That forces the wood to undergo volumetric changes along three planes resulting in axial, radial, tangential shrinkage. These changes are important to woodworkers because they cause the wood to warp, crack, shear, and bend.

When moisture content falls below the fiber saturation point, it affects wood properties, including mechanical strength, acoustics, and shrinkage.